First step: Select a country or the international website with all available languages

The production and the processing of green coffee

Coffee is an agricultural produce, just like wine.

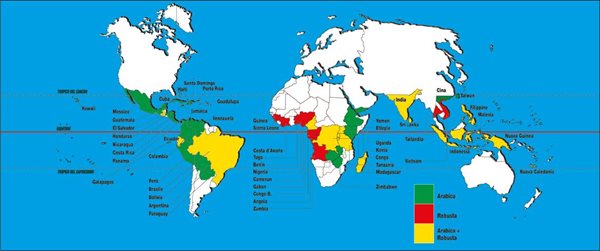

The same coffee plant produces fruit (beans, coffee) with different characteristics in aroma and flavour according to the country and place where it grows (height/humidity/soil characteristics).

Coffee beans are processed in the very same place where they grew.

The type of processing and the harvest of beans affect quality and aromas.

The roasting of coffee is chosen according to the extraction of the future drink (Turkish coffee – moka- percolation – espresso) and substantially affect aromas and flavour.

Roasting companies consider their mixings an intellectual property they keep secret.

Coffee plant species

The most cultivated species is called “coffee arabica”, which is immediately followed by “coffee canepora”, they are both very different in bean shape and colour.

The coffee qualities defined for trade by the ICA (International Coffee Agreement) are the following:

Colombian washed = arabica with water processing from Colombia – Kenya – Tanzania,

Arabica Central = arabica with water processing from all other countries,

Brazilian Natural = arabica and stout

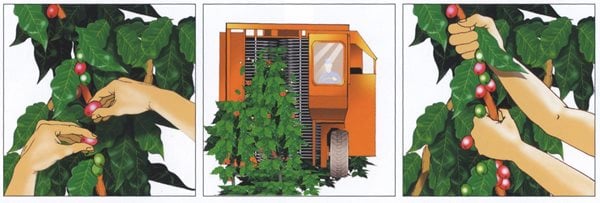

Coffee is harvested in 3 different ways:

1. Natural picking

This is the manual picking of single berries and allows a harvest of homogenous quality ripening, that is hard and costly.

2. Manual stripping

Manual stripping of the cherries off the branch

- inhomogeneous harvest

- picking is faster and less costly

- cherries are less likely to be damaged.

3. Mechanical stripping

Mechanical stripping

- inhomogeneous harvest

- fast and less costly

- cherries can be damaged

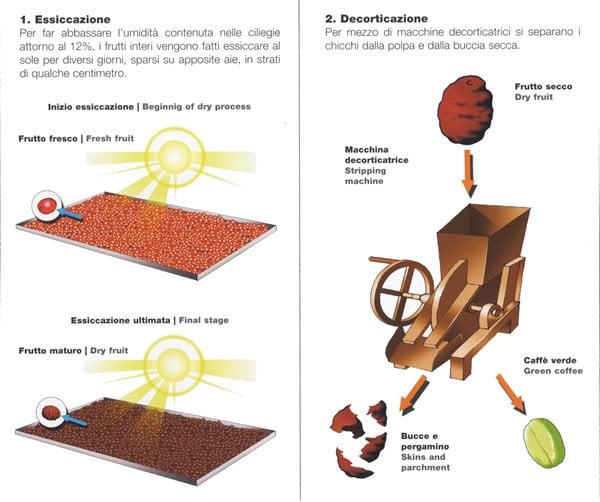

Once they have been harvested, coffee cherries have to be dried and separated from their pulp to obtain the raw coffee bean.

This processing method consists of 2 methods:

- Dry skinning processing

- Wet processing (washing)

Dry processing

Drying: in order to lower the humidity level of the cherries to 12%, the whole cherries are left to dry in the sun for several days, spread over special threshes in layers of a couple of centimeters.

Shelling: using shelling machines, the beans are separated from the pulp and the dry skin.

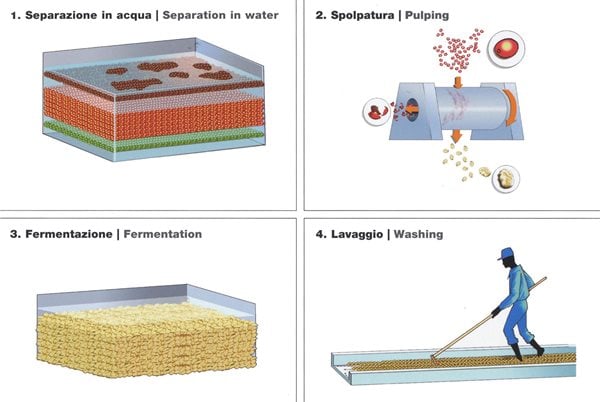

Wet processing

The cherries are soaked in fresh water tanks which, due to the differences in weight will force the ripe and unripe cherries to the bottom and the dry and rotten ones float.

The fruit from the first selection go through pulping machines, which disclose the beans in parchment.

The remaining pulp, as well as the mucilage left on the parchment beans, dissolves when the grains are soaked in fermentation tanks.

After the fermentation phase, the coffee beans, still in their parchment are washed in cement canals, where a further bean selection takes place according to density.

Selection and quality of coffee beans

There is no perfect processing method. Among coffee beans there may be soil residue, stones, twigs, etc. and the beans could be in part removed, treated, unripe or effected by moulds etc.

For this reason, great care is used in the selection of healthy beans and in the removal of dirt or other material.

This selection is performed with the use of complex automatic machines, which cannot always find all the defective beans.

After this stage there remains the job carried out by outright specialists coffee tasters, who work on behalf of purchasers and roasters

In fact transport can also substantially affect the quality of coffee beans.

Transport by ship-container and the possible contaminations and deterioration of quality.

The beans of raw coffee are packed in bags, placed on pallets and then into containers.

Transport is one of the most frequent causes of quality decay

- infiltration of water into the containers

- broken bags

- high humidity percentage in containers with subsequent building of condensation, if not suitably insulated.

Please note: in order to prevent damage caused by condensation, containers are insulated (coated) with cardboard panels.

The final test of the coffee tasters

Major coffee importers/traders as well as roasters avail themselves to real coffee “sniffer”-“taster” specialists.

A product with such an organoleptic characteristics and complex aromas and tastes as coffee can be assessed only by individuals with an exceptionally sensitive smelling and tasting qualities, and only after many years of training, experience and practice.

These rare specialists are able to perceive and identify the aromas and obviously also all defects in coffee too.

Sensory evaluation

Sight – smell – taste – tactile sensations – aftertaste

Information and images in this article were taken from the book "The espresso coffee production system" edited by Bazzara.

You will find further information on the world of coffee by reading the other articles of the sections Coffee.